In this article, we will delve into the concept of FRP, explore the benefits of FRP ladders, and highlight why FRP ladders are the ideal choice for work-at-height scenarios. We will also examine the key features of FRP ladders, discuss the safety benefits they offer, compare them to traditional ladders, and conclude by summarizing the overall advantages of using FRP ladders for work at height safety.

Section 1: What is FRP Ladder?

Fiberglass (FRP) ladders are renowned for their optimal durability and stability. Constructed with seven layers of high-quality fiberglass, these ladders possess a unique blend of lightweight design and robustness. This combination results in a material that showcases exceptional strength-to-weight ratio, durability, and stability.

Notably, FRP ladders offer additional safety features that set them apart. They are non-conductive, providing protection against electrical hazards by offering insulation of up to 30,000 volts. Furthermore, these ladders have an impressive weight-bearing capacity of up to 150 kg, ensuring reliable support for various work applications. As a result, FRP ladders find extensive utilization across diverse industries, including maintenance, warehousing, operations, aerospace and many more.

Type of FRP Ladders:

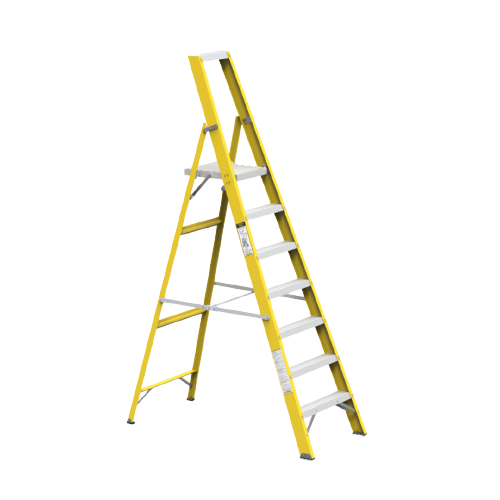

Step Ladder: Step ladders are self-supporting and feature an A-type design. They are ideal for tasks that require a freestanding ladder.

Uses: Home purposes, architecture & warehouse maintenance.

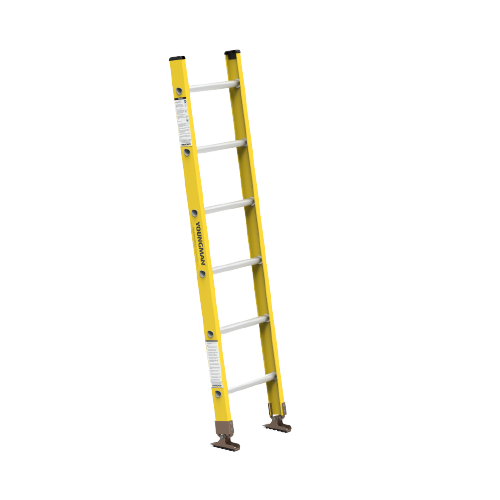

Straight Ladder: A straight ladder is the most basic and commonly used type of ladder. It consists of one long, straight section and is typically leaned against a surface for support.

Uses: Electrical poll, transmission lines, home purposes, warehouse maintenance.

Uses: Electrical poll, transmission lines, home purposes, warehouse maintenance.

Extension Ladder: Extension ladders consist of two or more sections that can be extended to reach greater heights. They are commonly used for tasks like painting or accessing roofs.

Uses: Electrical poll, transmission lines and tall structures where extended height is required.

Platform Ladder: Platform ladders are designed to provide a stable and secure platform for working at elevated heights and offer greater safety and convenience compared to traditional ladders. Equipped with safety rails or guardrails and handrails, ensuring that you can maintain your balance and have a secure area to work from.

Uses: Platform ladders are ideal where working at height is required for extended durations.

Highlighting the Benefits of FRP

FRP materials offer numerous advantages over traditional materials. They are non-conductive, making them suitable for electrical applications where safety is paramount. Additionally, FRP materials are highly resistant to chemicals and UV radiation, ensuring long-lasting performance even in harsh environments..

Section 2: Why Choose FRP Ladders for Work at Height?

Ensuring safety in work-at-height scenarios Work-at-height comes with inherent risks, including falls and electrical hazards. By choosing FRP ladders specifically designed for work at height, employers can mitigate these risks and provide a safe environment for workers. FRP ladders offer superior insulation properties, preventing electrical accidents and shocks when working near live wires or in electrical environments.

Comparing FRP ladders to traditional alternatives When comparing FRP ladders to traditional alternatives such as wood or metal, the advantages become evident. FRP ladders are significantly lighter in weight, making them easier to transport and maneuver. This feature is especially valuable when working at various locations or in confined spaces. Moreover, FRP ladders' non-conductive properties eliminate the risk of electric shock, offering added protection to workers.

Exploring the advantages of FRP ladders in different industries

FRP ladders find applications in a wide range of industries, including maintenance, repair and operations and more. Their corrosion resistance makes them suitable for outdoor use, even in challenging environments. The slip-resistant surface of FRP ladders ensures a secure grip, minimizing the risk of accidents. Furthermore, their lightweight nature allows for effortless handling, reducing strain on workers and enhancing productivity.

Section 3: Key Features of FRP Ladders

Lightweight and easy to transport One of the key features of FRP ladders is their lightweight nature. Compared to traditional alternatives, such as metal or wooden ladders, FRP ladders are significantly lighter, making them easier to carry and transport between work sites. This characteristic enhances portability and ensures that workers can quickly and efficiently set up the ladder wherever it is needed.

Non-conductive properties for electrical safety

Safety is a paramount concern when working near electrical sources. FRP ladders offer a crucial advantage in this regard - their non-conductive properties. Unlike metal ladders, which can conduct electricity and pose a significant risk, FRP ladders provide insulation and prevent electrical accidents. This feature enhances worker safety, especially in environments where live wires or electrical equipment are present.

Corrosion resistance and longevity

FRP ladders excel in durability due to their exceptional resistance to corrosion. Unlike traditional ladders made from metal or wood, FRP ladders are not susceptible to rust or decay. They can withstand exposure to harsh weather conditions, chemicals, and UV radiation without compromising their structural integrity.

Slip-resistant surface for enhanced grip

Safety is further enhanced by the slip-resistant surface of FRP ladders. The ladder rungs are designed to provide maximum grip, even in wet or slippery conditions. This feature significantly reduces the risk of accidents caused by slipping or losing balance while climbing or descending the ladder. Workers can have confidence in their footing, allowing them to focus on their tasks without unnecessary concerns.

EN131 Certified

FRP ladders undergo rigorous testing to ensure compliance with safety standards. The EN131 certification guarantees that FRP ladders meet the requirements for strength, stability, and performance. This certification provides reassurance that the ladder has been thoroughly assessed and is suitable for use in work-at-height scenarios.

ERDA Certified

FRP ladders are ERDA (Electrical Research and Development Association) certified. This certification ensures that our ladders meet the stringent safety standards set by ERDA, specifically in terms of electrical safety. When you choose FRP ladders, you can rest assured that they have undergone comprehensive testing and received approval for safe usage in environments with electrical hazards.

Section 4: Safety Benefits of FRP Ladders

Preventing electrical accidents and shocks

One of the primary safety benefits of FRP ladders is their non-conductive nature. This property eliminates the risk of electrical accidents or shocks when working near live wires, electrical equipment, or in electrical environments. FRP ladders provide a reliable barrier against electrical currents, protecting workers from potential harm.

Reducing the risk of falls and injuries

Falls from height are a significant concern in work environments. FRP ladders address this risk by providing a secure and stable climbing platform. The slip-resistant surface ensures workers have a firm grip, reducing the likelihood of slips or falls during ascent or descent. By using FRP ladders, employers can effectively minimize the risk of fall-related injuries and promote a safer working environment.

Enhancing stability and balance during work

Stability and balance are critical factors in ensuring safety when working at height. FRP ladders offer excellent stability due to their lightweight yet sturdy construction. Workers can feel confident and secure while performing tasks, knowing that the ladder provides a stable platform. This stability contributes to enhanced balance, reducing the chances of accidents caused by ladder wobbling or instability.

Compliance with safety regulations and standards

FRP ladders meet stringent safety regulations and standards, providing reassurance to employers and workers alike. Compliance with standards such as EN131 ensures that the ladder has undergone rigorous testing and meets the necessary requirements for strength, stability, and performance. By using FRP ladders, employers demonstrate their commitment to safety and adhere to industry best practices.

Lowering maintenance

Another safety benefit of FRP ladders is the reduced maintenance required compared to traditional alternatives. Unlike wooden ladders that require periodic inspections for rot or metal ladders susceptible to rust, FRP ladders are highly resistant to corrosion, decay, and UV damage.

Section 5: FRP Ladders vs. Traditional Ladders

When comparing FRP ladders to traditional ladders made of wood or metal, several material properties stand out. One of the most significant advantages of FRP ladders is their non-conductive nature. Unlike metal ladders, they effectively eliminate the risk of electrical accidents or shocks, providing enhanced safety for users. Offer superior corrosion resistance, eliminating concerns about rust or decay. Additionally, the lightweight nature of FRP ladders offers greater portability and ease of use compared to their heavier counterparts.

Highlighting Safety Advantages

The safety advantages of FRP ladders over traditional alternatives are significant. FRP ladders' non-conductive properties make them the ideal choice for electrical work or environments where live wires are present. Their slip-resistant surface reduces the risk of falls, ensuring worker safety. Moreover, their stability, combined with resistance to corrosion and decay, contributes to long-term safety and durability.

Conclusion:

FRP ladders are the epitome of safety and reliability in work-at-height scenarios. FRP ladders provide unmatched safety benefits with their exceptional features, including lightweight design, non-conductive properties, corrosion resistance, and slip-resistant surface. By choosing FRP ladders, employers can significantly reduce the risk of electrical accidents, falls, and injuries, while ensuring compliance with safety regulations.

Contact Y-Access Mfg Experts

If you are looking for a fiberglass ladder to prioritize safety, then check Y-Access Manufacturing (Formerly Youngman) range of ladders. Our products are designed to provide superior protection while ensuring maximum durability and longevity. Don't compromise on safety, choose Y-Access Manufacturing (Formerly Youngman) for all your ladder needs. Reach out to us at: sales@ymfg.co.in or call: +91-9015964626