Work-at-height practices are critical to the safety as well as the efficiency of warehouse operations. In the fast-paced world of warehousing, where goods are stacked high and tasks frequently involve accessing high areas, effective safety measures must be implemented to safeguard personnel from potential hazards. This article dives into the need for safe work-at-height practices and the right solution in warehouses and gives compelling statistics that highlight the importance of the right work-at-height solution.

In this article, you will discover:

How the right solution will enhance productivity and safety in your operations.

Gain valuable insights into selecting the right work platform for your specific warehouse requirements, ensuring maximum efficiency and performance.

Explore the innovative features and design elements of the warehouse work platform.

Statistics on Warehouse Accidents and Work-at-Height Incidents

Warehouse accidents can have severe consequences for both employees and the business. A comprehensive understanding of the statistics can drive home the importance of prioritizing safety measures in warehouses.

According to a report by the Occupational Safety and Health Administration (OSHA), falls are one of the leading causes of workplace fatalities.

Understanding the Importance of Safe Work-at-Height Practices in Warehouses:

In warehouses, employees work at elevated levels, performing tasks like stocking shelves and retrieving inventory. Prioritizing safety protocols is crucial due to potential risks.

Utilizing the right equipment, such as elevated platforms can empower workers to perform their work effectively and confidently. The right work-at-height solution for a warehouse depends on its specific needs, layout, and operations.

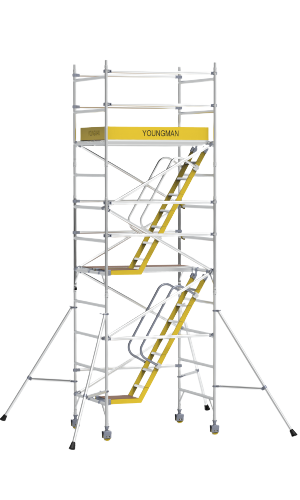

One effective solution is the use of the Youngman Warehouse ladder. A solution that offers elevated platforms for workers to conduct tasks safely and efficiently, even in confined spaces.

Identifying Different Work-at-Height Scenarios in Warehouses:

Warehouses are dynamic environments with diverse work-at-height scenarios that demand specific equipment and safety measures. Some common scenarios include:

Warehouse staff frequently need to access goods stored on high shelves. This scenario calls for equipment that provides sufficient height and stability

Maintaining & repair the warehouse infrastructure and equipment often requires workers to access elevated areas safely. Scaffolding solutions for these tasks.

Common Challenges Faced in Working at Heights:

Fall Hazards: The risk of falls from heights is a primary concern. Even seemingly minor falls can lead to severe injuries. Therefore, employing the appropriate equipment is crucial.

Limited Accessibility: Warehouses often have narrow aisles and confined spaces, making it challenging to use certain work-at-height solutions. Finding equipment that accommodates such constraints is essential.

Efficiency and Productivity: Ensuring that workers have easy access to heights can significantly impact productivity. Delays caused by inefficient work-at-height solutions can hinder warehouse operations.

Choosing the Right Work-at-Height Solution for the Warehouse:

After assessing the warehouse's work-at-height needs and understanding the challenges involved, selecting the appropriate solution becomes a pivotal decision. Here are some factors to consider:

Height Requirements and Reach: Evaluate the maximum heights workers need to reach in the warehouse. Choose equipment that provides sufficient elevation without compromising stability.

Limited Space: Carefully assess the warehouse layout and available area for work-at-height tasks. Choose compact equipment, such as the Single Width Aluminium Scaffold or Warehouse Ladder, to effectively operate in confined spaces.

Mobility and Versatility: If workers need to access different areas frequently, Warehouse Ladder can provide the necessary mobility and adaptability to frequently access the heights.

Safety Features: Prioritize equipment that comes with comprehensive safety features, such as guardrails, FRP channels, handrails, and anti-slip surfaces, to protect workers from fall hazards.

Innovative Work-at-Height Solutions for Warehouse

Warehouse Ladder: This type of work platform is ideal for industrial purposes, providing a reliable and sturdy solution for various tasks. With a load capacity of 150kg, it can accommodate workers and equipment, ensuring efficient operations within warehouses and industrial facilities.

Key Features of an Ideal Warehouse Work Platform:

Base frame heavy-duty powder coated: The base frame of the work platform is constructed using heavy-duty materials and coated with a durable powder coating finish. This ensures longevity and protects against corrosion, extending the platform's lifespan.

Handrails of High-quality Aluminium Alloy: The work platform is equipped with handrails made from high-quality Aluminium alloy. These handrails offer strength, durability, and improved safety for workers, providing a secure boundary to prevent accidental falls or slips.

Diagonal back support for better support and strength: To further enhance support and strength, the work platform incorporates a corresponding diagonal back support system. This feature reinforces the structure, increasing stability and preventing any potential sagging or weakening.

Aluminum scaffolding is another commonly used solution in warehouses. They offer better stability and height reach compared to ladders. Additionally, their modular design enables easy assembly and adaptability to various warehouse layouts. Scaffold towers are engineered to be quick and easy to assemble with minimal training can save you time and money on labor costs.

Advantages of Implementing the Right Work-at-Height Solution in Warehouses:

Improving Worker Safety and Reducing Accidents: Worker safety is of paramount importance in any work environment, especially in warehouses where employees often perform tasks at elevated levels. Implementing the best work-at-height solution can significantly enhance safety in the following ways.

Boosting Warehouse Productivity and Efficiency: Work-at-height solutions, such as warehouse ladders and aluminium scaffolds, provide access to elevated areas.. This increased accessibility streamlines various warehouse tasks

Cost Savings: Investing in the right work-at-height solution may seem like an upfront cost, but it can lead to substantial long-term savings.

In conclusion, prioritizing safe work-at-height practices in warehouses is essential for the well-being of employees and the success of the business. By understanding the statistics and risks associated with warehouse accidents, it becomes evident that investing in the right work-at-height solution is a wise choice. With the right work-at-height solution in place, such as warehouse work platforms and aluminium scaffolding, which enhance productivity, and worker safety, and optimize space utilization.